Enter ye in at the strait gate: for wide is the gate, and broad is the way,

that leadeth to destruction, and many there be which go in thereat:

Matthew 7:13

¶ A gentleman recently rode into my shop with bad wheel bearings. He needed a wide gate and a broad road because his bike was all over the place. A good thing he stopped. Those bad wheel bearings were definitely leading him to destruction.

Installing motorcycle wheel bearings is quite simple. The wheel usually has two bearings and two seals. One bearing and one seal on each side. In addition, the bearings are usually shielded on both sides, but not always. Between the bearings there is a spacer that the axle passes through. Older bikes may have three bearings and older bikes may or may not have shields. Most wheels will have ball bearings but some may have tapered roller bearings.

Repair is simple. Lever the seals out and then, with a drift, drive the bearings out. It helps to change the end of the drift from one side of the bearing to the other as you hammer the drift. Work your way all around the bearing so it does not get cock-eyed in the wheel as you drive it out. When both of the old bearings are out drive the new bearings back in, being careful to keep the bearing level and straight in the bore. Only drive the bearing in from the outside race, NOT the inside race. If you apply force to the inside race, all the force goes through the balls of the ball bearing, knocking them out of alignment and RUINING the bearing. Then replace the seals. Remember to place the bearing spacer in between the bearings before you drive the second bearing in. You can use a special seal/bearing driver to drive the bearings in or just turn a socket around and use it as a driver.

Drive the bearings out with a drift. |

Special Bearing Driver Tool. |

Bearing spacer. |

Wheel bearing driven in with a socket. |

Wheel hubs are made of aluminum so if you heat them up with a hot air gun the hub will expand and the bearings will come out and go in much easier. If the bearings are shielded on both sides you don't have to add any grease but I still like to put in plenty of grease into the hub just for the general principle of the thing. If the bearings only have one shield put the shielded side to the outside and pack the inside with lots of grease. On some mag wheel hubs adding extra grease is not practical. Don't worry, in principle there is enough grease in the sealed bearings to last the life of the bearing.

On some Mag wheels the center spacer can only go in from one side. This is because the wheel has a smaller inside hole on one side of the wheel, than on the other. On this type of wheel you need to be very careful when you drive the bearings out too. You must make sure your drift is pressing on the bearing and NOT on the inside of the wheel casting. If you are sloppy you will BREAK the wheel casting... VERY EXPENSIVE!

Large hole side of a Mag wheel. |

Small hole side of a Mag wheel. |

There are several kinds of tools to remove wheel bearing other then using a drift. One uses an expanding plug in the center hole of the bearing. Another uses two fingers to pull the bearing out. All involve putting pressure on balls of the bearing. This will ruin the bearing so if you have to drive out a bearing always replace it. On tapered roller bearings you can remove the bearing cone and regrease it because you are not driving it in or out with the rollers.

There are several kinds of tools to remove wheel bearing other then using a drift. One uses an expanding plug in the center hole of the bearing. Another uses two fingers to pull the bearing out. All involve putting pressure on balls of the bearing. This will ruin the bearing so if you have to drive out a bearing always replace it. On tapered roller bearings you can remove the bearing cone and regrease it because you are not driving it in or out with the rollers.

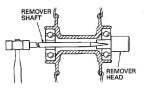

Instead of driving the bearing in with a hammer you can make a small press out of a threaded rod, nuts, washers, and a socket to slowly press the bearing into the hub.

Hand Made Bearing Press. |

Cross Section of a Press Tool. |

On occasion the inner race of the bearing and the balls will have been destroyed or are so badly damaged that they fall out when you try to drive out the bearing. If this happens you will have to grind a groove in the outer bearing race grinding stone. A Dremel tool works best for this but a regular drill with a small grinding stone will work too. Always wear safety goggles when you do this. Grind the outside bearing race, in one spot, till you just start to see the aluminum of the wheel. Grind it all the way across the width of the race. Once you grind the groove all the way across the width of the bearing it will normally come loose and you can pry the old race out with a small screw driver. Very rarely, it will really be rusted in there and you will need to put some penetrating oil on it and perhaps even grind another groove in another spot and take the bearing race out in pieces!

On occasion the inner race of the bearing and the balls will have been destroyed or are so badly damaged that they fall out when you try to drive out the bearing. If this happens you will have to grind a groove in the outer bearing race grinding stone. A Dremel tool works best for this but a regular drill with a small grinding stone will work too. Always wear safety goggles when you do this. Grind the outside bearing race, in one spot, till you just start to see the aluminum of the wheel. Grind it all the way across the width of the race. Once you grind the groove all the way across the width of the bearing it will normally come loose and you can pry the old race out with a small screw driver. Very rarely, it will really be rusted in there and you will need to put some penetrating oil on it and perhaps even grind another groove in another spot and take the bearing race out in pieces!

Replacement is the best option but sometimes you can repack used bearings with grease. If the bearings are tapered bearings or ball bearings without seals, the bearings can be easily repacked with grease. If the bearings are ball bearings with seals, things are a bit harder. If the shield is rubber you can usually pop it off, with a very thin screwdriver, without any damage. Then you just clean the bearing, add more grease, and pop the rubber shield back on.

If the bearings use a steel shield the shield will be almost impossible to get off. It can be done but usually the steel shield is bent and will not go back on. If the bearing is on an old piece of equipment, that you want to get going cheaply, it is possible to drill a small hole through the steel shield and then use a Needle Fitting on the end of your grease gun and pump in some grease. Very GROSS but it will work. You can also use the Needle Fitting to put grease into any bearing that has a rubber boot around it. Just push it through the rubber boot and pump in the grease. When you pull it out the rubber seals off the hole and sort of self heals.

Wheel bearings usually last quite a while, perhaps 15,000 to 30,000 miles. If you feel any play in the bearings replace them. If the wheel hub feels very hot to the touch, check to see if the brakes are dragging. If the brakes are not dragging, replace the bearings because there has been a lubrication failure. The bearings have overheated and are ruined. Likewise, if you have the axle out for some reason, like a tire change, and you notice it is discolored, as if it had been heated up with a torch, replace the bearings and the axle too. If you are going on a long trip and can't remember when you last replaced the wheel bearings, replace the bearings. If in doubt, replace the bearings. You only have two wheels. If one locks up at speed, you will be in BIG trouble!

|

|

Copyright © 1999-2007 dansmc.com. All rights reserved.